Wood is a natural material made of thousands of long fibers. With a magnifying glass you can see that these fibers are actually very small tubes through which water and nutrients flowed when the tree was alive.

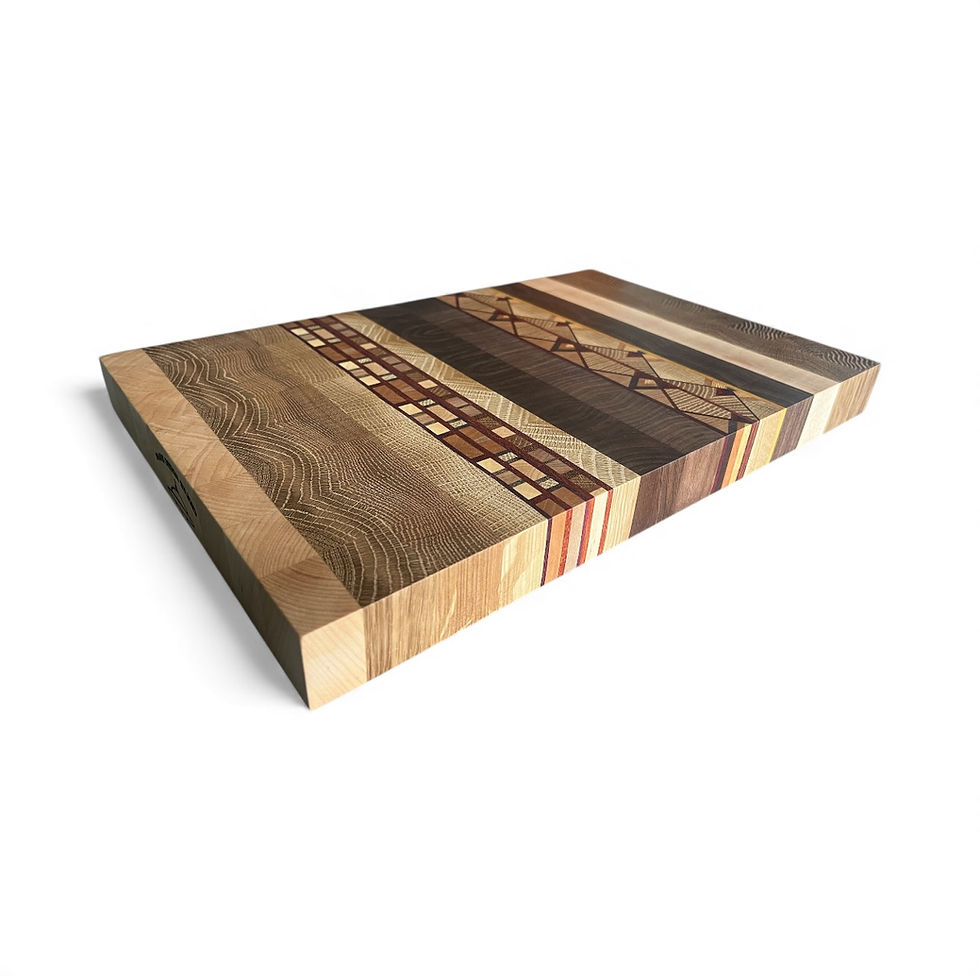

In an “end grain” board, the fibers are oriented vertically, so that you can see the thousands of cut ends. End-grain boards show less scarring, are easier on knives, and are preferred by professionals. End grain boards use the heaviest woods, typically oak or maple, and usually require more labor. Thus, they are often more expensive.

Many people enjoy the natural flow of fibers when they are oriented horizontally. This is called “face grain.” Face grain boards are beautiful and can function as light-duty cutting boards. Heavy use, however, will result in some scaring and your knives may need more frequent sharpening. Face grain boards are ideal for charcuterie, for use as trivets, and other uses where presentation is the primary consideration.

Unlike wood boards, plastic doesn't have “self healing” properties. Over time, cutting boards become too scarred to sanitize properly. When this happens, it's time to replace your plastic cutting board. When a plastic cutting board gets too scarred up, bacteria can hide in the deep crevices, even after washing.